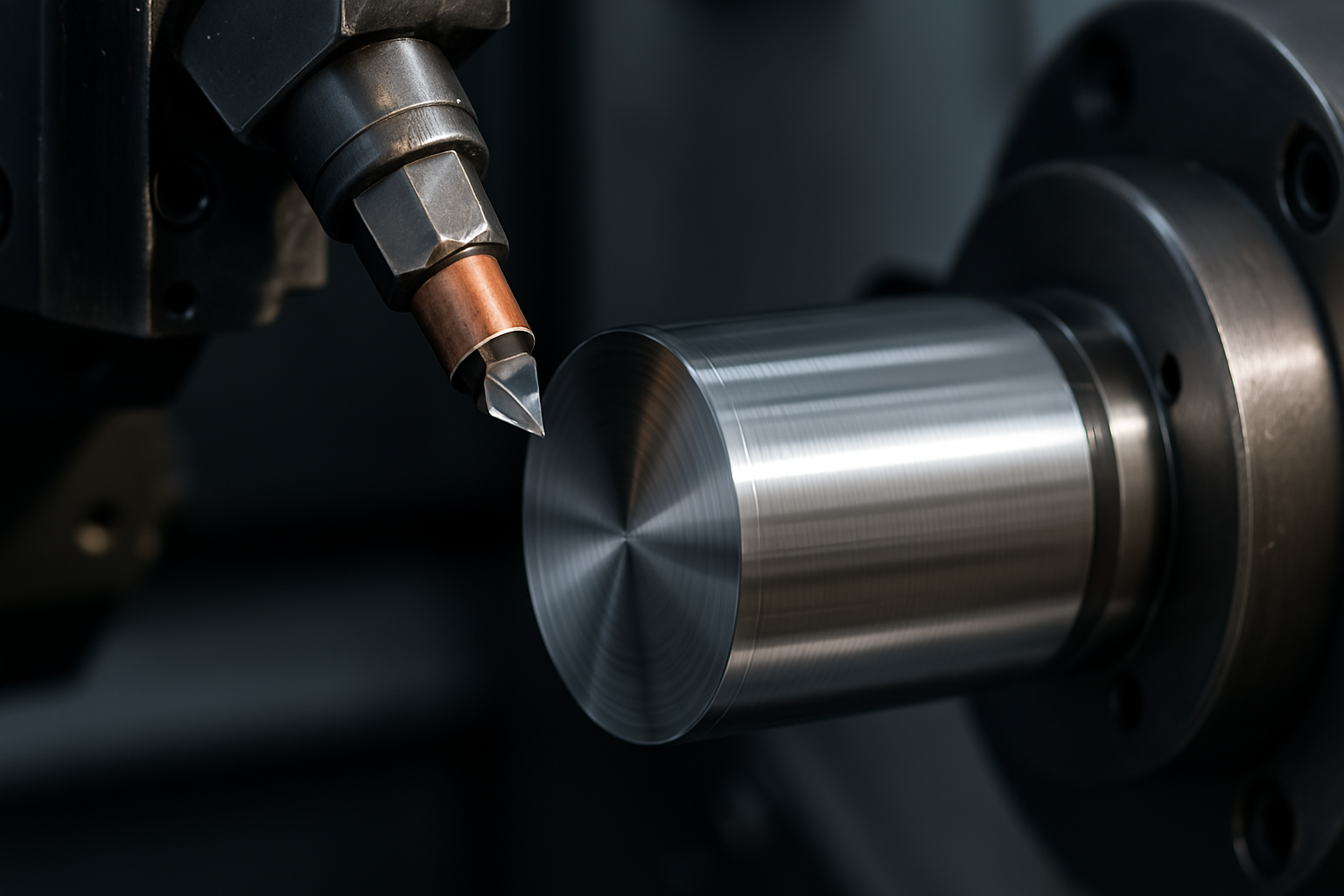

What does achieving 0.001mm accuracy in manufacturing really mean? Precision Technologies International stands at the forefront of this remarkable capability—a tolerance thinner than a human red blood cell.

In today’s demanding industrial landscape, precision manufacturing has evolved from a luxury to an absolute necessity. High-precision machining at this microscopic level enables critical components in aerospace, medical, and defense sectors to function with unprecedented reliability. Furthermore, these advanced engineering systems require not just specialized equipment but also rigorous quality control systems that Precision Technologies International has perfected over decades of operation.

This article explores how PTI achieves this extraordinary level of accuracy through specialized gear manufacturing processes, state-of-the-art equipment, comprehensive quality assurance protocols, and industry-leading certifications. Additionally, we’ll examine how their customization capabilities serve diverse client needs—from aerospace OEMs to specialized R&D projects requiring rapid prototyping.

Precision Gear Manufacturing Capabilities at PTI

At the core of Precision Technologies International’s manufacturing excellence lies their exceptional gear manufacturing capabilities. PTI has established itself as a premier gear manufacturer for challenging markets across the UK, offering extensive CNC gear grinding, cutting, spline shaping, and machining services that deliver bespoke components with extraordinary precision.

Gear Cutting Tolerances up to 0.001mm

PTI excels in producing precision-cut and ground gears to the most exacting specifications. Their Formula 1 engine gears are manufactured to master gear qualities ranging from DIN QU.3 to DIN QU.6, depending on specific customer requirements . While most engine gears fall between 2.0 and 3.0 module, PTI’s capabilities extend from manufacturing gears between 0.2 module to 12 module (180 D.P. to 2 D.P.) . This level of precision exceeds standard industry tolerances, with typical CNC machining tolerances usually ranging from ±0.05 mm to ±0.13 mm .

The company works with diverse materials, including general case hardening steels, aerospace steels, and tool steels . Moreover, their finished gears can undergo additional processes such as shot peening and super finishing when required . This commitment to precision has made PTI the manufacturer of choice for various motorsport applications, including F1, IRL, CART, A1GP, and historic engines .

Threaded Component Accuracy in Aerospace Applications

In aerospace manufacturing, threaded components require exceptional precision due to the extreme conditions they face, including high temperatures, pressures, and vibrations . PTI’s threaded components deliver the minute accuracy essential for aerospace applications, where components must provide secure connections that withstand significant stress and fatigue without failure .

For flight-critical applications, PTI produces threaded fasteners that maintain tight seals to prevent leaks and ensure optimal performance .The company’s precision threading capabilities are particularly crucial considering that threaded aerospace parts must adhere to Class 3A and 3B fit standards (where A indicates external threads and B indicates internal threads) . This represents the most critical category requiring the tightest tolerances in the industry.

Unlike conventional thread cutting, PTI employs advanced thread rolling processes that increase tensile strength, making threads harder and more compact . This method produces threads with tolerances as precise as ±0.0001″, helping to eliminate galling—a costly issue that can lead to loosening, seizing, and stripping of threads .

Spline Grinding for High Torque Transmission

Spline shafts play a vital role in mechanical systems by enabling precise motion control and reliable power transmission . PTI’s expertise in spline grinding produces components that transmit torque between a shaft and mating components such as gears, couplings, or hubs .

The company’s high torque type splines feature multiple ridges that engage with corresponding grooves in mating parts, ensuring secure mechanical connections that handle high rotational forces without slippage . Consequently, these precision-ground splines distribute load more evenly along contact surfaces, reducing stress concentration and wear while improving mechanical reliability under continuous or high-load operation .

PTI’s spline grinding capabilities support applications where timing, synchronization, and indexing are critical, such as in robotics, engine timing systems, and CNC machinery . Their high-precision splines allow for axial movement between connected components while still transmitting torque effectively , making them ideal for space-constrained environments where traditional keyed shafts would be too bulky.

Through a unique combination of skills, equipment, and metrology, PTI creates perfect components that exemplify precision engineering with precision delivery .

Advanced Equipment and Process Control Systems

Behind Precision Technologies International’s remarkable manufacturing prowess lies a sophisticated array of equipment and control systems that form the backbone of their ultra-precise operations.

CNC Multi-Axis Machines with Sub-Micron Resolution

Precision Technologies International employs advanced CNC machining centers equipped with multi-axis functionality that achieves remarkable sub-micron resolution. These sophisticated systems incorporate high-resolution measuring capabilities down to sub-micron levels, offering repeatable measurements with extraordinary precision. The integration of multi-axis scanning heads enables complex geometries and contours to be measured in a single setup, significantly enhancing efficiency without compromising accuracy .

For achieving true sub-micron precision, PTI utilizes grating interferometers that can detect positioning errors with resolutions as fine as 1 nanometer. This technology enables the measurement of multiple degrees of freedom simultaneously, including linear positioning, straightness, and angular errors—crucial for maintaining absolute precision across all dimensions.

In essence, these systems feature servo loops running at 20kHz, regardless of the number of axes in operation, thereby ensuring excellent axis synchronization and high dynamics. Advanced motion control algorithms effectively minimize jitter, reduce settling times, and prevent unwanted vibrations that could compromise precision . Indeed, measurements have confirmed that these systems achieve nanometer-level tracking errors during critical operations like wafer scanning .

Real-Time Process Monitoring with SPC Integration

Precision Technologies International has implemented comprehensive real-time monitoring systems that transform collected process data into actionable insights. Their Statistical Process Control (SPC) integration provides immediate visual process monitoring through centralized dashboards that display real-time control charts . These systems automatically update for optimized reporting and feature various chart types including I-MR, Xbar-R, Xbar-S, and EWMA charts.

The monitoring system allows operators to quickly identify when processes are operating normally (displayed as green), beginning to deviate (yellow), or experiencing significant deviations (red) . This color-coded visualization enables rapid response to process variations, thereby preventing out-of-specification production . Coupled with fault detection alerts, root cause analysis capabilities, and automatic corrective recommendations, the system maintains consistent quality across all manufacturing operations .

For traceability purposes, all inspection data is logged and stored digitally, ensuring complete tracking from raw material to finished part. The quality system integrates seamlessly with manufacturing and engineering departments, allowing for real-time data access, trend analysis, and immediate corrective actions when required .

Temperature-Controlled Machining Environments

At this point, temperature control emerges as one of the most critical factors in achieving sub-micron precision. Precision Technologies International maintains stringent temperature control in their machining facilities, keeping the environment between 15°C and 25°C to minimize thermal expansion or contraction of both equipment and workpieces . Even slight dimensional changes from temperature variations can lead to unacceptable deviations in high-precision components .

Furthermore, PTI employs preheat procedures for their machines, allowing them to run at low speed for 15 to 30 minutes before beginning production operations . This brings critical components like spindles and linear guideways to thermal equilibrium, effectively reducing dimensional errors during initial machining .

Alongside temperature management, humidity control between 40-60% RH prevents metal oxidation issues that could affect surface quality . The company has strategically designed their facility to avoid direct airflow from conditioning systems hitting the machines, as localized cooling can cause deformation and subsequent machining errors .

Through this integrated approach to equipment, process control, and environmental management, Precision Technologies International maintains their ability to consistently achieve the extraordinary 0.001mm accuracy that sets them apart in the precision manufacturing industry.

Quality Assurance and Metrology Standards

The foundation of Precision Technologies International’s extraordinary accuracy lies in their rigorous quality assurance and metrology standards. Quality verification at this level requires specialized laboratory capabilities and adherence to international standards that few manufacturers can match.

UKAS Accredited Laboratory for Dimensional Testing

Precision Technologies International maintains a UKAS accredited dimensional calibration laboratory that serves as the backbone of their quality verification system. This accreditation represents objective proof that PTI complies with ISO 17025 standards and follows best practices for calibration . UKAS accreditation essentially functions as an additional layer of insurance for the accuracy and reliability of dimensional measuring equipment .

Unlike standard calibration services, PTI’s UKAS accredited laboratory takes all variable factors of metrological and dimensional calibration into account, with particular attention to measurement uncertainty . For UKAS accreditation, laboratories must provide a 95% certainty of measurements, with full documentation and analysis of the remaining 5% uncertainty . This exceptional level of verification is crucial for industries like aerospace, automotive, and medical devices where component failure is not an option.

ISO 1328 and DIN 3970 Compliance in Gear Inspection

In gear manufacturing, Precision Technologies International strictly adheres to ISO 1328 and DIN standards that define the framework for gear accuracy. ISO 1328 specifically focuses on defining tolerances for gear tooth profiles, helix deviations, and pitch errors . This international standard is highly regarded for its flexibility, allowing manufacturers to specify different accuracy grades according to specific application requirements.

The company’s inspection processes follow a comprehensive approach where various parameters including tooth profile, lead, pitch, and runout are measured according to these standards. ISO 1328 uses an ascending order where lower numbers indicate higher precision , allowing PTI to quantify and document the exceptional accuracy of their gear products.

Accordingly, their quality systems allow for implementation of these standards through calibrated measurement instruments, thoroughly trained personnel, and meticulously documented procedures .This systematic approach ensures that all gear metrology is performed accurately and reliably, and that products consistently meet the required specifications and tolerances.

Use of CMMs with 0.0005mm Repeatability

Precision Technologies International employs state-of-the-art Coordinate Measuring Machines (CMMs) that achieve remarkable repeatability of 0.0005mm . These advanced metrology systems utilize high precision rotary tables that deliver precision geometry with axial performance well below 0.0005mm and positional accuracies to ±0.5 arc-seconds (±0.00014°) .

Notably, these CMMs incorporate air-bearing technology that ensures exceptionally good motion geometry of less than 0.0001mm for axial and radial runout . This level of precision is particularly crucial when measuring complex components like gears, where multiple dimensions must be verified simultaneously.

The company’s column measuring machines feature air-bearing Z and Y-axes that contribute to their extraordinary rigidity and measurement reproducibility . With scale resolutions of 0.0005mm, these systems comply with ISO 10360-2 measurement uncertainty standards .

Prior to any precision measurement, PTI’s laboratory follows strict environmental protocols. Temperature control is maintained between 15°C and 25°C to prevent thermal expansion or contraction that could compromise measurement accuracy. This attention to environmental factors, combined with their advanced CMM capabilities, ensures that Precision Technologies International can verify dimensions with confidence at the microscopic level their aerospace and precision engineering clients demand.

Certifications and Industry Accreditations

Certifications and industry accreditations serve as critical differentiators for Precision Technologies International, establishing a foundation of trust and credibility with clients in demanding sectors. These credentials validate the company’s commitment to excellence and provide objective evidence of their advanced capabilities.

AS9100 Rev D for Aerospace Quality Management

First and foremost, Precision Technologies International maintains AS9100D certification, the premier quality management standard specifically designed for aviation, space, and defense industries . This certification builds upon ISO 9001 requirements with additional aerospace-specific guidelines addressing product safety, configuration management, and risk management . AS9100D places significant emphasis on counterfeit parts prevention and human factors consideration in manufacturing processes . In practice, this certification enables PTI to participate in global aerospace supply chains, as their credentials are recognized worldwide . Customers benefit from documented procedures that identify corrective actions whenever defects occur, resulting in fewer nonconforming products and decreased production costs . AS9100D certification also demonstrates PTI’s dedication to delivering consistently reliable components for flight-critical applications.

ISO 9001:2015 for General Quality Systems

In addition to aerospace certification, Precision Technologies International maintains ISO 9001:2015 certification, the world’s most widely recognized quality management standard . Given these points, the company operates under a comprehensive framework that enhances customer satisfaction through consistent quality delivery . Their quality management system addresses seven key areas: organizational context, leadership, planning, support, operations, performance evaluation, and continuous improvement . This systematic approach helps PTI identify inefficiencies, reduce waste, and streamline operations . Beyond internal benefits, ISO 9001 certification provides customers with confidence that robust quality control processes are in place .

ISO 17025 for Laboratory Calibration Standards

Meanwhile, PTI’s laboratory operations maintain ISO 17025 accreditation, establishing their competence in performing precise testing and calibration activities . This credential is particularly valuable as it promotes confidence in measurement results both nationally and internationally . Throughout their laboratory processes, this standard ensures impartiality and consistent operation, reducing the need for additional supplier assessments . Above all, ISO 17025 accreditation validates that PTI’s metrology lab follows best practices for calibration with particular attention to measurement uncertainty . As a result, calibration certificates issued by PTI’s laboratory are accepted across borders without requiring additional testing, streamlining compliance for international clients.

Client-Specific Customization and Prototyping

Precision Technologies International excels in tailoring manufacturing solutions to unique client specifications across various industries. Their flexible production capabilities support diverse projects—from large-scale manufacturing to specialized component development.

Batch Production for OEM Aerospace Clients

Through close collaboration with leading aerospace and defense manufacturers, Precision Technologies International handles complex designs while maintaining supply chain efficiency . As an AS9100D and ISO 9001:2015 certified organization, they deliver precision components that meet stringent aerospace quality standards . Their skilled technicians utilize state-of-the-art machinery to produce custom aerospace parts that enable clients to develop agile supply chains for emerging markets .

Rapid Prototyping for R&D Projects

For research and development initiatives, Precision Technologies International offers expedited prototype creation services. Their capabilities allow engineers to quickly iterate between digital designs and physical prototypes, often completing the process within a day. This rapid turnaround enables multiple design iterations based on real-life testing results . Hence, clients can evaluate concepts side-by-side, understand the look and feel of designs beyond virtual visualization, and gather actionable user feedback .

Single Operation Sub-Contract Processing

Besides full production services, Precision Technologies International provides specialized sub-contract processing. Their capabilities include high-precision single operations that complement clients’ in-house manufacturing processes . Typically, these services encompass precision machining, measurement, and validation—all performed within tightly controlled environments to maintain sub-micron accuracy .

Conclusion

Precision Technologies International stands as a remarkable example of manufacturing excellence, consistently delivering components with extraordinary 0.001mm accuracy. This level of precision, thinner than a human red blood cell, results from their exceptional combination of specialized gear manufacturing processes, cutting-edge equipment, and rigorous quality control systems.

Throughout their operations, PTI demonstrates unmatched expertise in gear cutting, thread component manufacturing, and spline grinding. Additionally, their advanced CNC multi-axis machines with sub-micron resolution work within temperature-controlled environments to maintain consistent accuracy. Real-time process monitoring with SPC integration ensures production quality never wavers.

The company’s UKAS accredited laboratory, compliance with ISO 1328 and DIN 3970 standards, and use of coordinate measuring machines with 0.0005mm repeatability all contribute to their exceptional quality assurance. Likewise, their AS9100 Rev D, ISO 9001:2015, and ISO 17025 certifications validate their commitment to excellence across aerospace, defense, and other demanding industries.

PTI has therefore established itself as an ideal partner for diverse manufacturing needs – from batch production for OEM aerospace clients to rapid prototyping for R&D projects and specialized sub-contract processing. The company’s ability to deliver microscopic precision undoubtedly enables critical components in aerospace, medical, and defense sectors to function with unprecedented reliability.

This commitment to precision manufacturing ultimately represents far more than technical achievement. Rather, it embodies the extraordinary human capability to push engineering boundaries and create components that meet the most demanding specifications in modern industry. Precision Technologies International thus continues to set the standard for manufacturing excellence measured not in millimeters, but in microns